In the concrete production industry, material sourcing is one of the most significant factors influencing concrete mixing plant cost. The quality, availability, and transportation of raw materials directly affect production efficiency, operational expenses, and overall profitability. For entrepreneurs considering a concrete batching plant business or exploring investment opportunities such as concrete plant business for sale in Australia or a concrete batching plant in UAE, understanding how material sourcing impacts cost is essential for making informed decisions.

The Role of Material Sourcing in Concrete Production

Concrete is primarily composed of cement, aggregates (sand, gravel, or crushed stone), water, and admixtures. The cost and quality of these raw materials play a crucial role in determining the concrete mixing plant cost. Poor-quality materials can lead to lower concrete performance, higher waste rates, and increased maintenance, which all contribute to elevated operational expenses. Conversely, sourcing high-quality materials locally or efficiently can reduce costs while ensuring consistent concrete quality.

For a concrete batching plant business, the ability to secure reliable and cost-effective material suppliers is a competitive advantage. It affects not only the price of each cubic meter of concrete but also the long-term profitability of the operation.

Cement: A Major Cost Component

Cement is one of the most expensive and critical components of concrete. Its price is influenced by global supply, local production capacity, and transportation costs. Sourcing cement locally can significantly reduce concrete mixing plant cost by lowering freight charges and minimizing delays.

In regions like Australia, a concrete plant business for sale in Australia often emphasizes proximity to cement suppliers to maintain cost efficiency. Similarly, in the UAE, establishing a concrete batching plant in UAE close to cement production facilities or distribution hubs ensures lower operational costs and continuous supply, which is vital for large-scale construction projects.

Aggregates: Quality and Availability

Aggregates account for the largest portion of concrete by volume, making them a major factor in material costs. The price of aggregates depends on availability, extraction costs, and transportation. Using locally sourced aggregates reduces haulage costs and energy consumption.

However, the quality of aggregates—such as particle size distribution, moisture content, and cleanliness—affects concrete workability and strength. Low-quality aggregates can increase wastage and result in higher maintenance costs for mixers and conveyors, ultimately raising the concrete mixing plant cost.

For entrepreneurs entering the concrete batching plant business, assessing the availability of high-quality aggregates near the proposed plant site is crucial. Locations with abundant natural sand, gravel, or crushed stone offer a cost advantage compared to areas where aggregates must be imported or transported over long distances.

Water and Admixtures

Water and chemical admixtures are essential for controlling concrete properties, including workability, setting time, and durability. The cost of water may seem minimal, but in arid regions such as the UAE, sourcing water can significantly affect operational expenses. Admixtures, while small in volume, are often expensive and should be procured from reliable suppliers to avoid inconsistencies that can lead to concrete defects.

When planning a concrete plant business for sale in Australia, entrepreneurs should consider the local availability of high-quality admixtures and water sources to maintain concrete standards while controlling costs. Efficient water recycling systems and proper admixture dosing can help minimize waste and further reduce operational expenses.

Transportation and Logistics

Transportation is a key factor linking material sourcing to concrete mixing plant cost. Even if raw materials are inexpensive, high transport costs can significantly increase overall expenses. Plants located near quarries, cement factories, or industrial suppliers benefit from reduced delivery costs and shorter lead times.

For example, a concrete batching plant in UAE strategically placed near construction hubs can serve multiple projects efficiently, reducing both transportation and labor costs. Similarly, a concrete plant business for sale in Australia will attract investors if it demonstrates access to low-cost, high-quality raw materials with minimal logistics challenges.

Bulk Purchasing and Supplier Contracts

Securing long-term contracts with suppliers allows concrete plant operators to stabilize material prices, reducing fluctuations in concrete mixing plant cost. Bulk purchasing can also result in discounts, further lowering expenses. For entrepreneurs entering the concrete batching plant business, evaluating supplier reliability, delivery schedules, and pricing agreements is essential for maintaining a competitive edge.

Impact on Plant Design and Operations

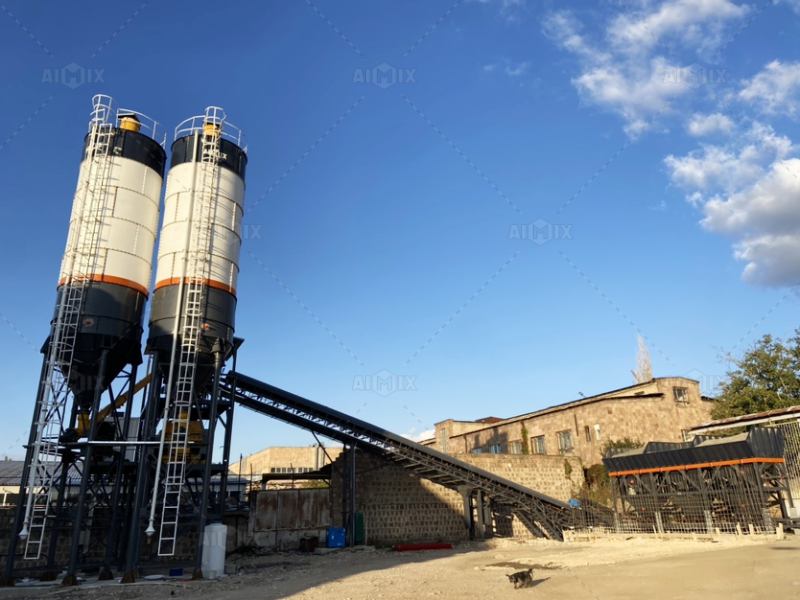

Material sourcing influences not only cost but also the design and operation of a concrete mixing plant. Plants must be equipped to handle varying aggregate sizes, moisture levels, and recycled materials if applicable. Poorly matched plant design can lead to higher maintenance costs and production inefficiencies.

By considering material availability and quality upfront, investors and operators can choose the right type of plant, such as stationary or mobile concrete batching plants, and optimize workflows to reduce labor, energy, and maintenance costs.

Conclusion

Material sourcing is a critical factor affecting concrete mixing plant cost and overall profitability in the concrete industry. From cement and aggregates to water and admixtures, each component contributes to the total operational expense. Strategic sourcing, local procurement, bulk purchasing, and efficient logistics play key roles in minimizing costs while ensuring consistent concrete quality.

For entrepreneurs interested in a concrete batching plant business, or those exploring opportunities such as a concrete plant business for sale in Australia or establishing a concrete batching plant in UAE, careful evaluation of material sources is essential. By prioritizing proximity to high-quality suppliers, negotiating favorable contracts, and implementing efficient logistics and recycling systems, plant operators can optimize production, reduce costs, and achieve sustainable growth in a competitive market.