The concrete batching plant market is poised for significant growth in 2025, driven by expanding infrastructure projects, urbanization, and increasing demand for ready-mix concrete. As construction companies look for reliable and efficient solutions to meet their growing needs, the demand for concrete batching plants is on the rise. With various batching plant types available—ranging from ready-mix concrete plants to mobile and stationary concrete batch plants—buyers must carefully evaluate their requirements to make the right investment.

In this article, we will explore the trends and factors shaping the concrete batching plant for sale market in 2025, including the different plant types, technological advancements, and how concrete batch plant manufacturers are adapting to the needs of modern construction projects.

1. Batching Plant Types: Understanding Your Options

When looking for a concrete batching plant for sale in 2025, it is essential to understand the different batching plant types available and their specific applications. The two main categories include stationary batching plants and mobile batching plants, each with its advantages and limitations.

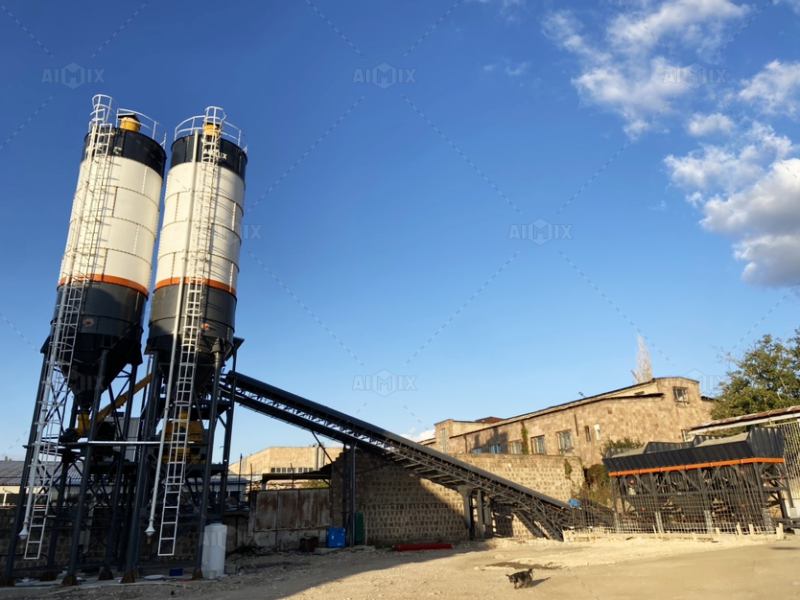

Stationary Batching Plants

Stationary batching plants are large, fixed systems designed for long-term use in large-scale construction projects. They are ideal for projects that require a steady supply of concrete, such as road construction, high-rise buildings, and industrial complexes. These plants are known for their high production capacity, making them a popular choice for contractors dealing with high-volume concrete production.

Advantages of Stationary Batching Plants:

Higher production capacity and efficiency

Suitable for large-scale and long-term projects

Offers accurate and consistent concrete mixing

Lower operational costs over time

Mobile Batching Plants

On the other hand, mobile batching plants are portable and can be relocated from one site to another. These plants are often used in smaller or temporary projects, offering the flexibility to move between construction sites without the need for a permanent installation. Mobile batching plants are popular in projects like residential developments, roadworks, and smaller infrastructure projects.

Advantages of Mobile Batching Plants:

Easy to transport and set up at different sites

Flexible and suitable for small to medium-sized projects

Lower initial investment compared to stationary plants

Reduced transportation costs for on-site concrete production

Ready-Mix Concrete Plants

For projects where large volumes of concrete need to be supplied on demand, a ready mix concrete plant is a highly efficient solution. These plants produce ready-mix concrete that can be delivered to construction sites, reducing the need for on-site mixing and saving time.

Advantages of Ready-Mix Concrete Plants:

Ensures uniform quality of concrete

Ideal for large-scale projects where consistent concrete supply is needed

Reduces labor and mixing time on-site

2. Technological Advancements in Concrete Batching Plants

As the construction industry continues to innovate, concrete batching plant manufacturers are integrating advanced technology to improve the performance and efficiency of their plants. In 2025, buyers will see several cutting-edge features in concrete batch plants that make them more automated, energy-efficient, and environmentally friendly.

Automation and Control Systems

Automation has become a standard in the concrete batching plant industry. Modern plants are equipped with automated control systems that enable operators to monitor and adjust mixing processes remotely. These systems increase the accuracy and consistency of concrete batches, reducing human error and ensuring high-quality production.

Benefits of Automation in Concrete Batching Plants:

Increased production efficiency and reduced human intervention

Remote monitoring and diagnostics for faster troubleshooting

Consistent concrete mix and improved overall quality

Enhanced data reporting and analytics for better decision-making

Energy-Efficiency and Sustainability

With growing concerns about sustainability, concrete batching plant manufacturers are focusing on developing more energy-efficient plants. Advances such as solar-powered batching plants, recycling systems for water and aggregates, and lower-energy motors are becoming increasingly common. These innovations help reduce energy consumption, lower operating costs, and minimize the environmental impact of concrete production.

Sustainability Benefits of Modern Batching Plants:

Reduced carbon footprint and energy costs

Water and material recycling systems minimize waste

Compliance with environmental regulations and sustainability goals

IoT Integration for Predictive Maintenance

The Internet of Things (IoT) is transforming the way batching plants are monitored and maintained. IoT sensors embedded in plant components allow for continuous data collection, which can be analyzed to predict potential equipment failures before they occur. This predictive maintenance approach helps prevent downtime and reduces repair costs.

Advantages of IoT-Enabled Batching Plants:

Predictive maintenance improves plant uptime

Reduced maintenance costs and repair time

Enhanced overall plant efficiency

3. What to Look for When Buying a Concrete Batching Plant in 2025

Given the variety of options available, buyers should be well-informed when looking for a concrete batching plant for sale. Here are some key factors to consider:

Production Capacity and Output

Determine the required production capacity based on your project’s concrete demands. A stationary batching plant offers high capacity, while a mobile batching plant may be more suitable for projects with variable concrete needs.

Quality and Consistency of Concrete

The quality and consistency of the concrete produced are critical for the success of your project. Choose plants that offer accurate control over mix ratios and consistent output, especially for large-scale or long-term projects.

Cost and Financing Options

The initial cost of purchasing a batching plant can be significant. Make sure to evaluate the total cost of ownership, including installation, maintenance, and operational costs. Many manufacturers offer flexible financing options to make the investment more accessible.

After-Sales Support and Warranty

Choose concrete batch plant manufacturers that offer strong after-sales support, including warranties, installation assistance, and ongoing maintenance. This ensures your plant operates efficiently over its lifespan and minimizes downtime.

Flexibility and Scalability

As your business grows, your concrete production needs may change. Ensure that the plant you purchase offers scalability and can be upgraded with additional features or higher production capacity as required.

4. Conclusion: The Concrete Batching Plant Market in 2025

The concrete batching plant market in 2025 is shaped by technological advancements, increased demand for efficient concrete production, and the growing importance of sustainability. Whether you opt for a stationary batching plant, mobile batching plants, or an RMC batching plant, modern solutions are offering higher efficiency, cost-effectiveness, and eco-friendly operations.

As concrete batch plant manufacturers continue to innovate, businesses looking for a batching plant for sale will have a wide range of options to choose from, each with its own set of advantages. By understanding the various plant types and the latest technological advancements, companies can make an informed investment that will benefit them for years to come, ensuring high-quality concrete production and improved profitability in the competitive construction market.